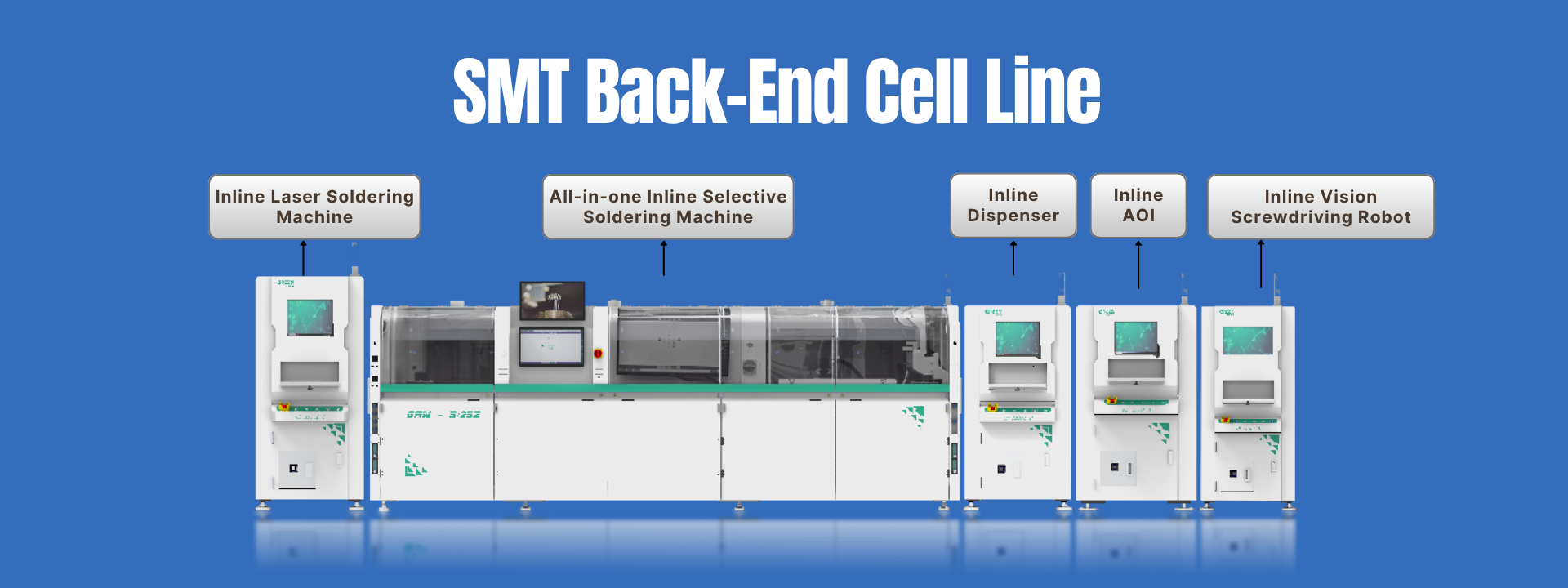

Kugwiritsa ntchito kwa SMT-back-end cell line mumakampani amagetsi a 3C

GREEN ndi National High-Tech Enterprise yodzipereka ku R&D ndikupanga zida zamagetsi zamagetsi zamagetsi ndi zida zoyesera za semiconductor & kuyesa.

Kutumikira atsogoleri amakampani monga BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, ndi mabizinesi ena 20+ a Fortune Global 500. Wokondedwa wanu wodalirika pamayankho apamwamba opanga.

Surface Mount Technology (SMT) ndiye njira yayikulu pakupanga zamagetsi zamakono, makamaka pamakampani a 3C (makompyuta, kulumikizana, zamagetsi zamagetsi). Imayika zida zopanda lead / zazifupi (SMDs) molunjika pa PCB, zomwe zimapangitsa kuti zikhale zolimba kwambiri, zocheperako, zopepuka, zodalirika, komanso zopanga zopanga.Momwe mizere ya SMT imagwiritsidwira ntchito mumakampani amagetsi a 3C, ndi zida zazikulu ndi magawo opangira ma cell a SMT kumbuyo.

□ Zogulitsa zamagetsi za 3C (monga ma foni a m'manja, mapiritsi, ma laputopu, mawotchi anzeru, zomverera m'makutu, ma routers, ndi zina zotero) zimafuna kuchepetsedwa kwambiri, mbiri yocheperako, magwiridwe antchito apamwamba,ndi mofulumira

iteration.SMT mizere imakhala ngati nsanja yapakati yopangira yomwe imakwaniritsa zofunikira izi.

□ Kukwaniritsa Kuchepa Kwambiri Kwambiri ndi Kupepuka:

SMT imathandizira makonzedwe ang'onoang'ono (mwachitsanzo, 0201, 01005, kapena zopinga zing'onozing'ono / ma capacitor; tchipisi tating'ono ta BGA/CSP) pa PCBs, kuchepetsa kwambiri bolodi

phazi, kuchuluka kwa chipangizo chonsecho, ndi kulemera kwake - chothandizira kwambiri pazida zonyamula ngati mafoni a m'manja.

□ Kuyang'anira High-Density Interconnect & High Performance:

Zogulitsa zamakono za 3C zimafuna magwiridwe antchito ovuta, zomwe zimafuna ma PCB amtundu wapamwamba kwambiri (HDI) ndi njira zingapo zovutirapo. Maluso oyika bwino a SMT amapanga ma

maziko amalumikizidwe odalirika a mawaya olimba kwambiri komanso tchipisi tapamwamba (mwachitsanzo, mapurosesa, ma module amakumbukiro, mayunitsi a RF), kuwonetsetsa kuti zinthu zikuyenda bwino.

□ Kukulitsa Kuchita Bwino Kwambiri & Kuchepetsa Mtengo:

Mizere ya SMT imapereka makina apamwamba kwambiri (kusindikiza, kuyika, kubwereza, kuyang'ana), kutulutsa mwachangu kwambiri (mwachitsanzo, mitengo yoyika kuposa 100,000 CPH), komanso kulowererapo pang'ono pamanja. Izi

imawonetsetsa kusasinthika kwapadera, zokolola zambiri, ndipo imachepetsa kwambiri mtengo wagawo lililonse popanga zochuluka-kugwirizana bwino ndi 3C product'demands kuti mugulitse mwachangu komanso

mitengo yampikisano.

□ Kuwonetsetsa Kudalirika Kwazinthu & Ubwino:

Njira zotsogola za SMT-kuphatikiza kusindikiza kolondola, kuyika kolondola kwambiri, mbiri yoyendetsedwa bwino, komanso kuyang'ana mozama kwa inline-kutsimikizira kusasinthika kwa mgwirizano wa solder ndi

kudalirika. Izi zimachepetsa kwambiri zolakwika monga zolumikizira kuzizira, kutsekereza, ndi kusalumikizana bwino kwa zinthu, kukwaniritsa zofunikira zokhazikika zogwirira ntchito za 3C mwankhanza.

malo (mwachitsanzo, kugwedezeka, kuyendetsa njinga zotentha).

□ Kusintha kwa Rapid Product Iteration:

Kuphatikizika kwa mfundo za Flexible Manufacturing System (FMS) kumathandizira mizere ya SMT kuti isinthe mwachangu pakati pa mitundu yazogulitsa, kuyankha mwachangu kukusintha kwachangu.

zofuna za msika wa 3C.

Laser Soldering

Imayatsa zitsulo zoyendetsedwa bwino ndi kutentha kuti ziteteze kuwonongeka kwa zigawo zotentha. Imagwiritsa ntchito kusalumikizana komwe kumathetsa kupsinjika kwamakina, kupewa kusamutsidwa kwazinthu kapena PCB kusinthika - kukhathamiritsa malo opindika / osakhazikika.

Selective Wave Soldering

Ma PCB okhala ndi anthu amalowa mu uvuni wa reflow, pomwe mawonekedwe a kutentha omwe amayendetsedwa bwino (kutentha, kuthira, kutulutsanso, kuzizira) amasungunula phala la solder. Izi zimathandiza kunyowetsa mapepala ndi chigawo chotsogolera, kupanga zomangira zodalirika zazitsulo (zolumikizira zogulitsira), zotsatiridwa ndi kulimba pakuzizira. Kuwongolera kwa curve ndikofunika kwambiri pamtundu wa weld komanso kudalirika kwanthawi yayitali.

Kupereka Kwathunthu Kwachangu Kwambiri Pamizere

Ma PCB okhala ndi anthu amalowa mu uvuni wa reflow, pomwe mawonekedwe a kutentha omwe amayendetsedwa bwino (kutentha, kuthira, kutulutsanso, kuzizira) amasungunula phala la solder. Izi zimathandiza kunyowetsa mapepala ndi chigawo chotsogolera, kupanga zomangira zodalirika zazitsulo (zolumikizira zogulitsira), zotsatiridwa ndi kulimba pakuzizira. Kuwongolera kwa curve ndikofunika kwambiri pamtundu wa weld komanso kudalirika kwanthawi yayitali.

Makina a AOI

Kuyang'ana kwa AOI pambuyo pa Reflow:

Pambuyo pogulitsanso, makina a AOI (Automated Optical Inspection) amagwiritsa ntchito makamera owoneka bwino kwambiri komanso mapulogalamu opangira zithunzi kuti angoyang'ana okha mtundu wa ma solder pa PCB.

Izi zikuphatikizapo kuzindikira zolakwika monga:Kuwonongeka kwa Solder: Kusakwanira/kuchulukirachulukira, zolumikizira zozizira, kulumikiza.Zowonongeka Zazigawo: Kusalinganiza bwino, zigawo zomwe zikusowa, zigawo zolakwika, polarity yosinthika, miyala yamanda.

Monga gawo lofunikira lowongolera khalidwe mu mizere ya SMT, AOI imatsimikizira kukhulupirika kwa kupanga.

Vision-Guided Inline Screwing Machine

M'kati mwa mizere ya SMT (Surface Mount Technology), dongosololi limagwira ntchito ngati zida zogwirira ntchito pambuyo pa msonkhano, kuteteza zigawo zazikulu kapena zomangira pa PCBs-monga kutentha kwa kutentha, zolumikizira, mabatani a nyumba, ndi zina zotero.