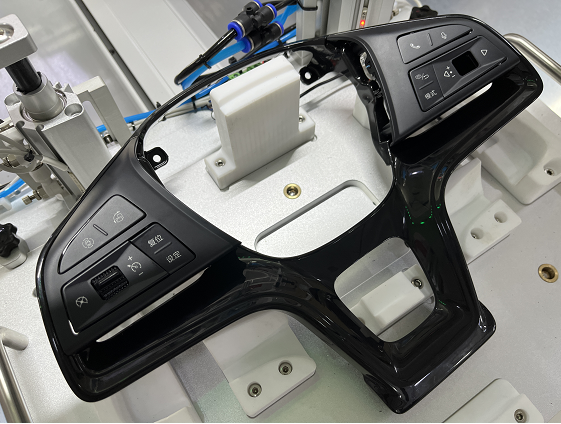

Makina Okulitsa a Robot Adsorption a Four-axis Type Screw Tightening Machine

Chipangizo Parameter

| chinthu | Zofotokozera |

| Chitsanzo | GR-XFSZ600/GR-XFSZ800 |

| Kufika kwa robot | 600mm/800mm |

| Dzina la Brand | ZOGIRIRA |

| Mawu osakira | makina screw |

| Kudyetsa shaft sitiroko | 500mm/800mm |

| Kukula (L*W*H) | 1300*1000*1950mm/1500*1200*1950mm |

| Mphamvu yosungirako pulogalamu | 0-1200 mm / s |

| Kuthamanga kwa axis | 999 magulu |

| Lock-up bwino | single screw ili pafupi 2.0-2.5S |

| Lock-up zokolola | 99.98% |

| Ntchito magetsi | AC220V |

| Gwero la mpweya wogwira ntchito | 0.4-0.7MPa |

| mphamvu | Pafupifupi 1.5KW |

Mawonekedwe a chipangizo

1.Kuyimirira-yekha kwapaintaneti, nsanja yodyetsera imasuntha kuti izindikire kudyetsa / kutulutsa kwazinthu, ndipo kulumikizana kwa loboti ya thefour-axis kumazindikira kutsekeka kwa screw.

2.IPC kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake;

3.Kuwonetsera kwazithunzi za malo otsekera ndi zotsatira zokhoma, kulemba chizindikiro cha OK / NG screw points, kufufuza mwachidwi komanso mofulumira;

4.Ogwiritsa ntchito ambiri, kasamalidwe ka zilolezo zamagawo angapo, oyang'anira amatha kupanga maakaunti atsopano ndikugawira zilolezo zogwiritsa ntchito mapulogalamu

5.CCD-assisted teaching screw coordinate points to remove manual visual positioning errors;CCD visual positioning correction coordinate points,luntha kuphatikiza kukonzedwa kwamagulu angapo a Mark points,Kupititsa patsogolo kuphasa koyamba kwa kujambula;

6.Support kuzindikira alamu monga loko lotayirira, kutsetsereka mano, kuyandama ndi zina zotero.Mapulogalamu amabwera ndi ntchito yoyandama yokonza kutalika;

7.7.Z-olamulira akhoza okonzeka ndi laser kusamutsidwa sensa (zoyandama kutalika muyeso), downforce kudziwika kachipangizo (ngati mukufuna);

8.Gulu lamagetsi likhoza kukhala ndi batch yamagetsi ya HIOS, batch yamagetsi ya Qili speed, batch yamagetsi ya servo, batch yamagetsi yanzeru, etc. (ngati mukufuna);

9.Zida zimatha kukweza MES malinga ndi zosowa za makasitomala, monga makokedwe, kuchuluka kwa makhoti, ngodya, chithunzi chokhotakhota, ndi loko.

10.Manual code scanning ndi automatic code scanning zitha kusankhidwa (posankha)

Deta ya 11.Production ikhoza kutsatiridwa, ndipo pulogalamuyo imabwera ndi kanban kanban. Mitundu yonse ya deta ikhoza kukwezedwa ndikutsitsa (posankha); 12.Automatic torque spot cheki, sungani zotsatira za cheki cha torque ndipo mutha kufunsa (posankha).

Tsatanetsatane Onetsani