Kugwiritsa ntchito mu Semiconductor Viwanda

GREEN ndi National High-Tech Enterprise yodzipereka ku R&D ndikupanga zida zamagetsi zamagetsi zamagetsi ndi zida zoyesera za semiconductor & kuyesa. Kutumikira atsogoleri amakampani monga BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, ndi mabizinesi ena 20+ a Fortune Global 500. Wokondedwa wanu wodalirika pamayankho apamwamba opanga.

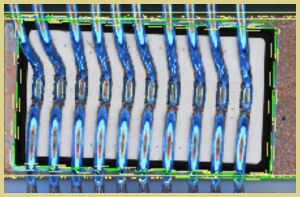

Makina omangira amathandizira kulumikizana kwapang'ono ndi ma diameter a waya, kuonetsetsa kukhulupirika kwa chizindikiro; formic acid vacuum soldering imapanga zolumikizana zodalirika pansi pa okosijeni <10ppm, kuteteza kulephera kwa okosijeni muzosunga zolimba kwambiri; AOI imalepheretsa zolakwika za micron-level. Synergy iyi imatsimikizira> 99.95% zokolola zapamwamba zonyamula, kukwaniritsa zofunikira zoyesa za tchipisi ta 5G/AI.

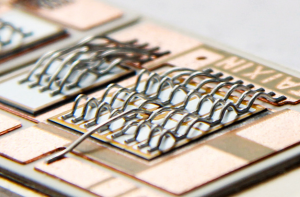

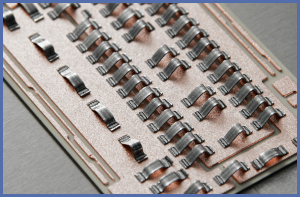

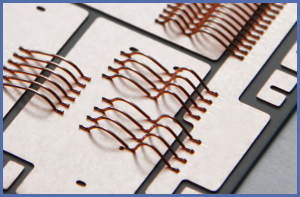

Akupanga Waya Bonder

Wotha kumangirira waya wa aluminiyamu 100 μm–500 μm, waya wamkuwa 200 μm–500 μm, nthiti za aluminiyamu m’lifupi mpaka 2000 μm m’lifupi ndi 300 μm wandiweyani, komanso nsinga zamkuwa.

Maulendo: 300 mm × 300 mm, 300 mm × 800 mm (customizable), ndi kubwereza <±3 μm

Maulendo oyenda: 100 mm × 100 mm, ndi kubwereza <±3 μm

Kodi Wire Bonding Technology ndi chiyani?

Kumangirira waya ndi njira yolumikizira ma microelectronic yomwe imagwiritsidwa ntchito kulumikiza zida za semiconductor kumapaketi awo kapena magawo ake. Monga imodzi mwaukadaulo wofunikira kwambiri pamsika wa semiconductor, imathandizira kulumikizana kwa chip ndi mabwalo akunja pazida zamagetsi.

Zida Zolumikizira Waya

1. Aluminiyamu (Al)

Kuwongolera kwapamwamba kwamagetsi motsutsana ndi golide, zotsika mtengo

2. Mkuwa (Cu)

25% yapamwamba yamagetsi / matenthedwe kuposa Au

3. Golide (Au)

Mulingo woyenera kwambiri wa conductivity, kukana dzimbiri, komanso kudalirika kolumikizana

4. Siliva (Ag)

Kuthamanga kwambiri pakati pazitsulo

Aluminium Waya

Aluminium Riboni

Waya Wamkuwa

Riboni ya Copper

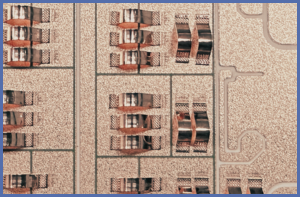

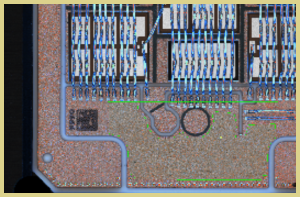

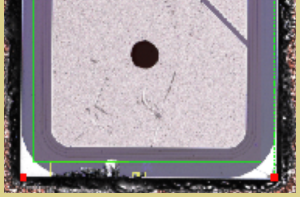

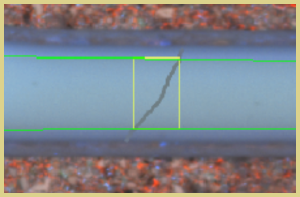

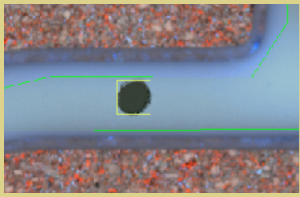

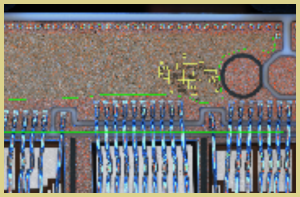

Semiconductor Die Bonding & Wire Bonding AOI

Imagwiritsa ntchito kamera yamafakitale ya 25-megapixel kuti izindikire zolakwika zomangika ndi waya pazinthu monga ma IC, IGBTs, MOSFETs, ndi mafelemu otsogolera, kukwaniritsa chiwongola dzanja choposa 99.9%.

Milandu Yoyendera

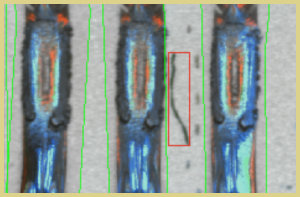

Wokhoza kuyang'ana kutalika kwa chip ndi flatness, chip offset, kupendekera, ndi kupukuta; solder mpira sanali adhesion ndi solder olowa detachment; Kuwonongeka kwa mawaya kuphatikiza kutalika kapena kusakwanira kwa loop, kugwa kwa loop, mawaya oduka, mawaya osowa, kulumikizana ndi mawaya, kupindika mawaya, kuwoloka, ndi kutalika kwa mchira; zomatira zosakwanira; ndi metal splatter.

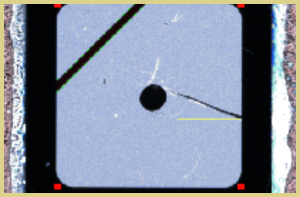

Mpira wa Solder / Zotsalira

Chip Scratch

Kuyika kwa Chip, Dimension, Tilt Meas

Chip Kuipitsidwa/Zinthu Zakunja

Chip Chipping

Ceramic Ngalande ming'alu

Kuwonongeka kwa Ceramic Trench

AMB Oxidation

In-Line Formic Acid Reflow Oven

1. Kutentha kwakukulu ≥ 450 ° C, vacuum level osachepera <5 Pa

2. Imathandizira mapangidwe a formic acid ndi nitrogen process

3. Mlingo wopanda kanthu wa mfundo imodzi ≦ 1%, mulingo wonse wopanda kanthu ≦ 2%

4. Kuziziritsa kwamadzi + kuziziritsa kwa nayitrogeni, kokhala ndi makina oziziritsa madzi komanso kuziziritsa kukhudzana

IGBT Power Semiconductor

Kuchulukirachulukira pakusokonekera mu IGBT soldering kumatha kuyambitsa kulephera kwamaketani kuphatikiza kuthawa kwamafuta, kuwonongeka kwamakina, komanso kuwonongeka kwamagetsi. Kuchepetsa kuchuluka kwa zinthu zopanda kanthu kufika pa ≤1% kumawonjezera kudalirika kwa chipangizo komanso kugwiritsa ntchito mphamvu.

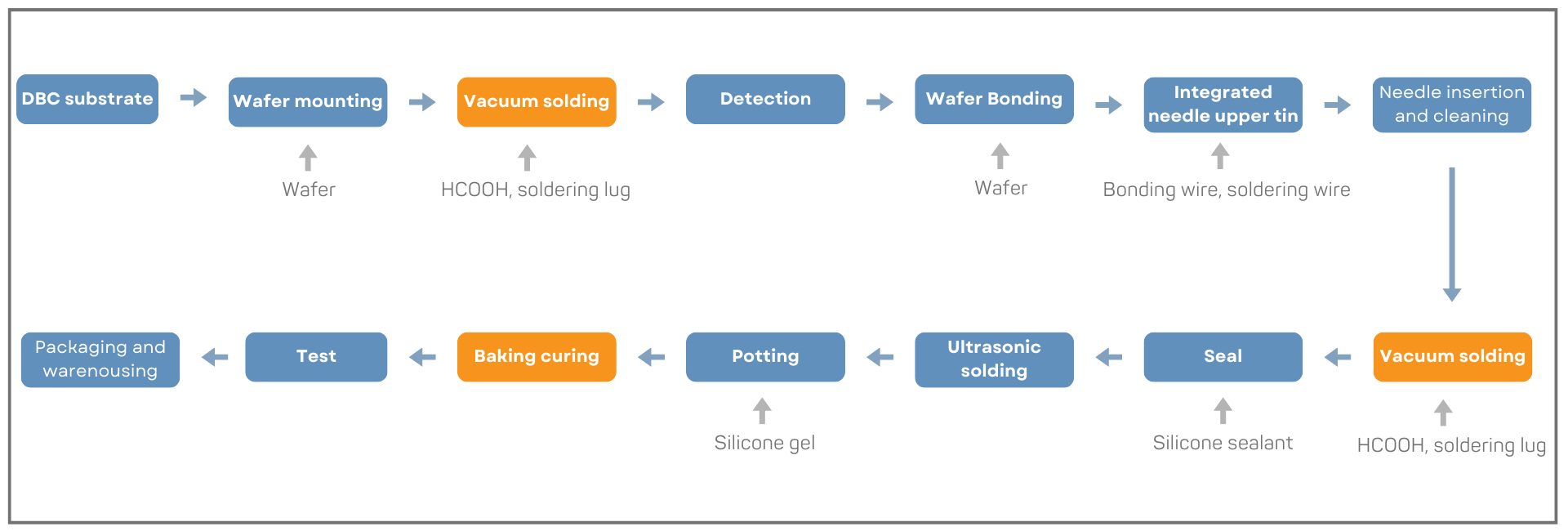

IGBT Production process flow chart